The sublimation process allows dye to go from a solid to a gas without turning to liquid, a bit like dry ice. The conversion is initiated by heat and controlled by pressure. First, a design is printed with dyes onto special release paper. The dyes used turn into gas when brought under heat and pressure and then permanently transfers onto a poly coated substrate like metal, glass, ceramic, fabric, to name a few. The effects are permanent and less prone to fading, as the dye is embedded in the substrate rather than simply laying on top like a normal print.

The process is almost like a tattoo, but instead of for your skin, it’s for your chosen product. The heat opens up the pores of the poly coating, then with the applied pressure the dye transfers, cools and returns to a solid form embedded in the substrate.

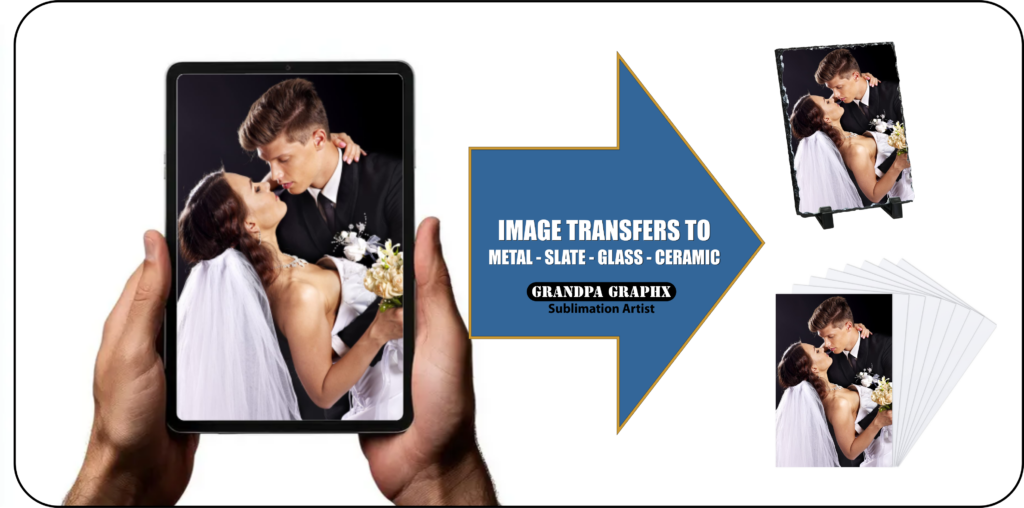

The result is a permanent, full color image that won’t crack, peel or wash away from the substrate.